Beneficiation Lab

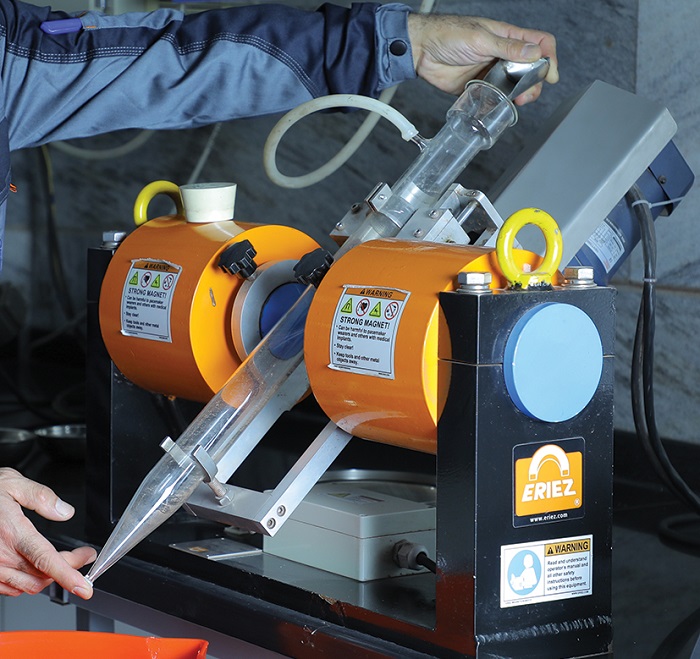

Magnetic separation

FIMRC has extensive expertise in magnetic separation. We have a wide selection of equipment for bench and pilot scale testing, so we can fulfil requirements for many commodities. Our equipment can either be used in a stand-alone mode for individual sample processing or integrated with other operation units in a processing flowsheet or recycling industries.

FIMRC has extensive experience (hundreds of projects) in the following fields.

Providing flowsheet development for iron ore using bench scale magnetic equipment

Developing flowsheets through pilot scale separators or installing pilot scale magnetic separators

Providing expertise to assist with the commissioning of the magnetic separators within the plant

Conducting audits of existing operations

Providing troubleshooting / diagnostic assistance

Our equipment include both bench and pilot scale equipment:

Wet and Dry Drum separators, including rare earth element drums

Davis Tube separators

Rare earth element magnetic separators

FIMRC offers mineral magnetic separation tests ranging from small-scale testing projects to full-scale pilot plant tests. Our capabilities include wet and dry magnetic separation in low, medium and high intensity fields of up to 20,000 gauss.

gravity separation

Gravity separation is one of the accepted techniques of concentrating minerals and FIMRC has significant expertise in this technology for many commodities. Gravity separation is an attractive operation unit as it generally has low capital and operating costs and uses few chemicals that might cause environmental pollution concerns. In addition to these, recent development of new equipment has enhanced the range of separations possible.

FIMRC experts can develop bench-scale flowsheets, pilot scale testing and plant audit and optimization services, depending on the needs of a project or facility.

We offer:

Gravity Separation Testing, including spirals concentrators, jigs and shaking tables

Multi Gravity Separation (MGS)

FIMRC technical experts can integrate, design, commission, maintain, and troubleshoot gravity separation systems. With our wide array of equipment and based on our extensive production experience, we can readily provide effective processing flowsheets and advise best operational practices during plant start-up.

Bond tests

The grinding circuit is one of the largest capital investments and high-priced operating costs. FIMRC can reduce the risk by combining different test procedures and design methodologies to ensure that this critical part of the plant is optimized. Our philosophy is to determine the variability of the ore using rigorous comminution testing, including Bond tests for ball mills at the first step.

Here is an overview of the Bond Test available at FIMRC: The test determines the Bond Ball Mill Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements.

W = Wi (10/√P – 10/√F)

W = Net power consumption in kWh/t

Wi = Bond work index (either Imperial or Metric units)

P = The 80% passing size of the ground product in µm

F = The 80% passing size of the feed in µm

The test is a closed circuit dry grindability test performed in a standard ball mill. It can be performed at mesh sizes ranging from 28 mesh to 400 mesh. The Feed Sample Requirements is 10 kg of minus 6 mesh sample.

Flotation

FIMRC has earned the reputation as the most experienced and trusted organization involved in flotation circuit flowsheet design and troubleshooting. Our core philosophy is to understand the variability of the ore parameters that affect flotation performance and then design, optimize or forecast the circuit performance based on these parameters. With standardized testing, cutting-edge mineralogy, an excellent suite of bench and pilot scale equipment and experienced technical experts, we provide mineral processing laboratory and pilot test programs designed to achieve the objectives quickly and efficiently.

Beyond flowsheet development and piloting of traditional flotation circuits, we offer you a comprehensive combination of flotation circuit expertise, technologies and equipment, including:

Oxide and reverse flotation

Reagent scheme development

MFT test

Locked cycle test

Process mineralogy

Contact cell flotation

Flotation equipment

Dewatering & Thickening

Strong ties to a broad range of equipment and flotation reagent suppliers ensure we have effective, practical, and innovative methods for mineral separation. Flotation is an incredibly robust and versatile process that is well accepted around the world. It works equally well on mixed sulphide, oxide, silicate and other ores. It relies on generating a population of bubbles of suitable size that can carry the hydrophobic target mineral up to be recovered.

Through visualizing and understanding the “hidden” factors of flotation and cell hydrodynamics, FIMRC has gained the expertise to provide you with reliable data and solutions for more efficient flotation.

Our typical project flow includes:

Our mineralogy technologies ensures that our metallurgists understand the mineral deportment and liberation and so can optimize the circuit early in the design stage

Flowsheet development is done on carefully selected samples that represent the major ore types in a deposit

Piloting to prove the flowsheet and review the impact of recycle streams, bleed stream and impurity build-ups

Locked-cycle tests are done to prove the basic flotation circuit flowsheet