Pilot Beneficiation

Pilot beneficiation

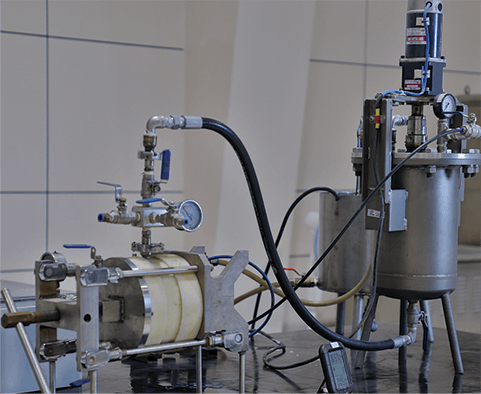

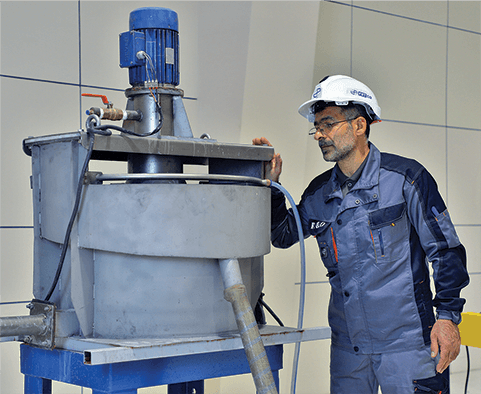

Pilot plant testing is used to demonstrate and confirm that the flowsheet developed at the bench scale is viable. Our pilot plant equipment are unique in that they operate in an integrated fashion, all operation units work to provide continuous feed or product typically resulting in the generation of concentrates. Bleed streams and impurity build-ups are also studied. Pilot plant tests are performed at a variety of scales, typically ranging from < 100 kg/hr. to > 1 ton/hr.

For new projects, piloting demonstrates operational viability, “proof-of-concept”, and produces market samples of the final product that can be expected, thus reducing technical risks. Piloting also generates metallurgical data that can be used to design the full-scale plant, thus reducing design and capital risks. Existing operations can also be simulated at pilot-scale to evaluate new equipment or technologies, assess the impact of different ore types or troubleshoot problems without interrupting production at the main plant.

Typical activities that can be undertaken during pilot testing include:

Establishing flowsheet viability. This is especially important for complex deposits, those utilizing new or unusual technologies or projects that are located in high-risk areas

Evaluating the impact of local water supply

Developing a water balance

Quantifying the impact of ore variability

Producing byproducts for specialized testing

Generating bulk samples for market evaluation

By means of efficient cooperation with well-known universities and research institutes. FIMRC experts also present their experience and knowledge through publishing the investigation and analytical results in international conferences and journals.