Digitalization

Digitalization

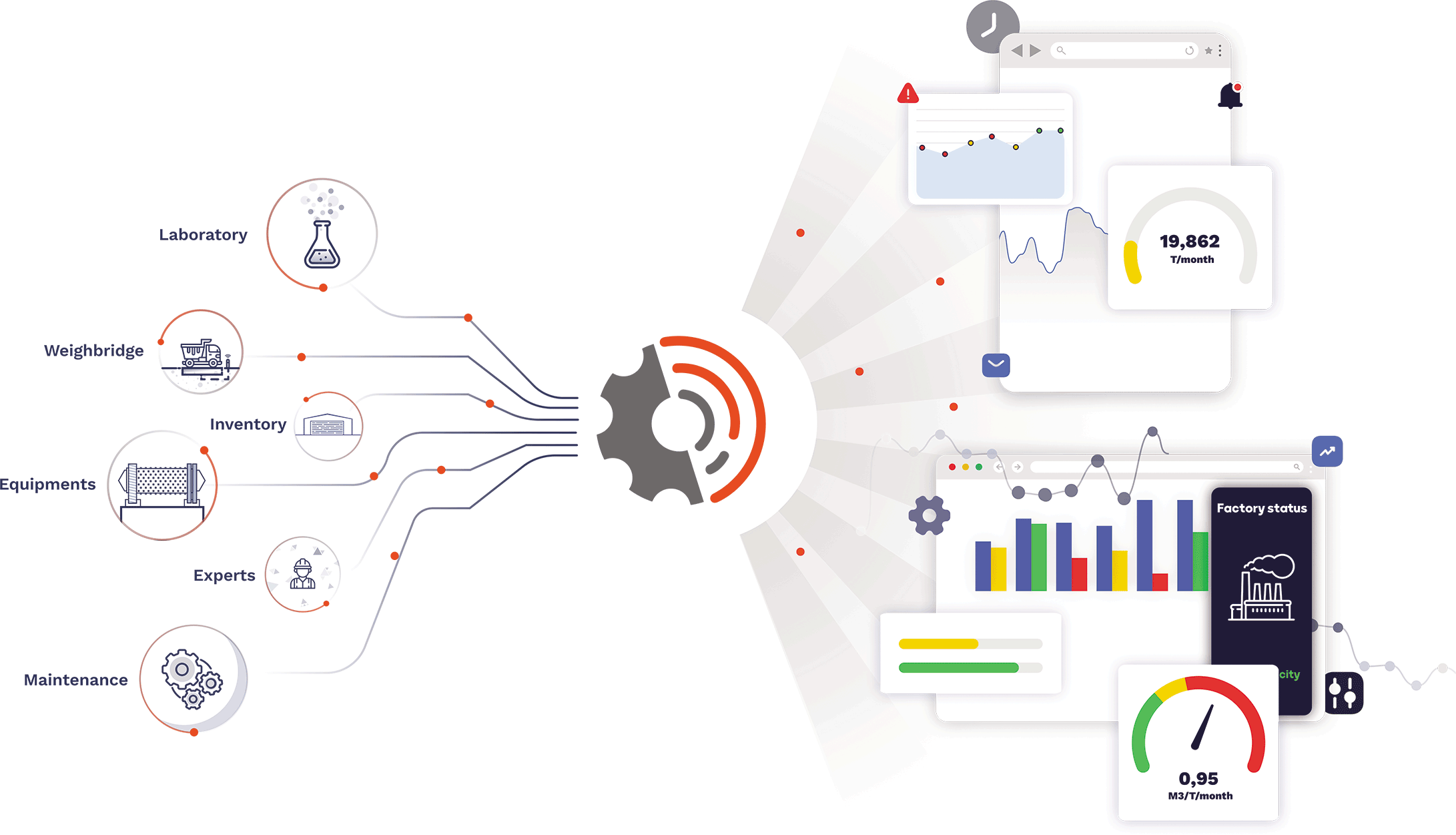

One of the most important challenges in commissioning and beneficiation of large industrial plants is limited access to vital information for factory management. This critical information originates from sources including instrumentation and sensors, laboratory, maintenance, inventory, additional wireless sensors for condition monitoring, industrial vehicles, site personnel location and health, as well as the valuable knowledge of experts and managers.

The mineral processing and metallurgy plants commissioned by FSTCO have deployed the Smart Pro for better management through online monitoring and analysis of industrial knowledge. This solution has equipped our plant management team, including top managers as well as process and maintenance engineers with online real-time dashboards.

The Smart Pro solution, which has been developed by FST`s partner company Aranuma, includes Remote Human Machine Interface (HMI), Mobile Application, Management Dashboard, Analytical Dashboard, and Admin Dashboard.

Using Smart Pro solution, our managers and engineers monitor the most important Key Performance Indicators (KPIs) which can be grouped into the followings:

Equipment’s sensors

Energy and materials consumption

Quality and quantity of process streams

Equipment maintenance knowledge

Planned production values

Alarms and symptoms

Plant’s working hours

Failure causes and related solutions

Efficiency and mass recovery values

Smart Production

In the smart effective production system deployed by FSTCO through Smart Pro solution, producing high-quality products with competitive prices has become feasible. The main advantage of smart industrial management includes the following:

1. Visualization

Monitoring and supervising the entire production operations in construction, commissioning and operation phases.

2. Processing

Investigation of important production events that occurred in the past using complex data analytics.

3. Alarm

Finding relationships between industrial events and defining good and bad patterns for future planning and monitoring.

4. Analytics

Deploying Artificial Intelligence (AI) tools to predict industrial events and implement smart production planning.